15 December, 2025

Share:

Polyester sludge dewatering belts are critical components in modern solid-liquid separation processes, widely employed in belt presses, screw presses, and other dewatering equipment. Their performance directly impacts dewatering efficiency, operational cost, and system stability. This article analyzes the key characteristics, advantages, and application considerations of polyester dewatering belts, providing a reference for selection and optimization in various industrial and municipal settings.

1. Performance Introduction

Sludge dewatering is an essential step in wastewater treatment, reducing volume and weight for cost-effective disposal or further processing. Polyester sludge dewatering belts as the primary filtering medium, must withstand extreme mechanical, chemical, and hydraulic conditions. Polyester monofilament has emerged as the dominant material for high-performance dewatering belts due to its superior balance of properties.

2. Key Characteristics and Advantages of Polyester sludge dewatering belts

A. High Strength & Abrasion Resistance: Polyester filaments offer excellent tensile strength and resilience, allowing belts to withstand high operational tensions and the abrasive nature of sludge solids, resulting in extended service life.

B. Outstanding Dimensional Stability: The belts maintain consistent mesh structure and width under varying conditions of moisture, heat, and pressure. This stability ensures uniform dewatering performance and prevents tracking issues on the machine.

C. Good Hydrolytic & Chemical Resistance: Polyester demonstrates strong resistance to water absorption and degradation across a broad pH range (typically suitable for common municipal and many industrial sludges), enhancing durability in wet environments.

D. Anti-Microbial Properties: The synthetic material resists mildew and bacterial growth, facilitating easier cleaning and maintenance, and reducing odor-related issues.

E. Design Flexibility: Manufacturers can engineer belts with specific properties by varying:

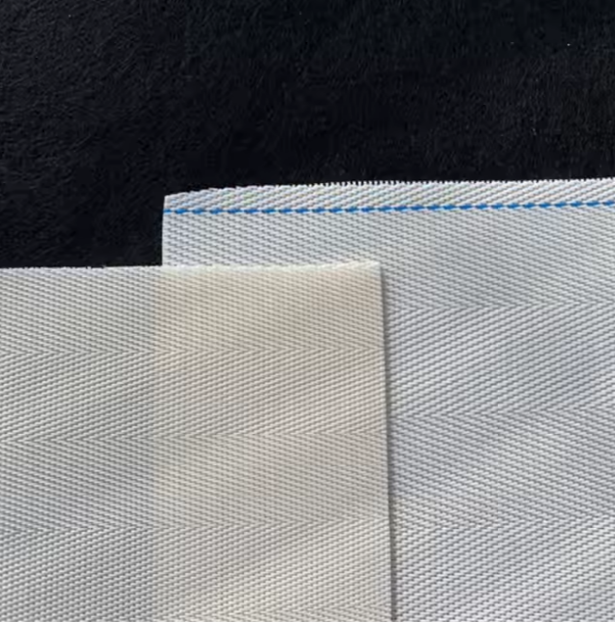

· Weave Pattern: Plain weave (standard, stable), twill/satin weave (smoother surface, better cake release, higher water flow).

· Mesh Count/Aperture Size: Tailored to retain specific particle sizes, balancing solid capture rate with water permeability.

·Thickness & Air Permeability: Affecting dewatering speed, pressing efficiency, and mechanical robustness.

F. Good Cake Release: A properly selected smooth surface weave promotes cleaner separation of the dewatered cake from the belt, reducing clogging and improving efficiency.

Application Analysis

Polyester sludge dewatering belts Primary Application Areas:

1. Municipal Wastewater Treatment Plants: For dewatering primary, secondary (activated), and digested sludge.

2. Industrial Wastewater Treatment:

· Pulp & Paper: Fiber-rich sludge.

· Textile & Dyeing: Chemical sludge.

· Electroplating & Metal Processing: Heavy metal hydroxide sludge.

· Petrochemical, Pharmaceutical, and Food Processing: Various organic and chemical sludges.

3. River & Dredging Projects: Volume reduction of dredged sediments.

Selection Criteria for Optimal Application:

Choosing the correct Polyester sludge dewatering belts is crucial. Key factors include:

1. Sludge Characteristics: Particle size distribution, viscosity, fiber content, and chemical composition determine the required mesh size and weave type.

2. Dewatering Equipment Type: The belt must match the exact specifications (length, width, joint type – commonly spiral or clip/pin seam) of the belt press or screw press.

3. Performance Goals: Target cake dryness, hydraulic throughput, and solid capture rate guide the selection of permeability, surface texture, and strength.

4. Operational Environment: pH levels, presence of oils/greases, or abrasive materials may necessitate special treatments (e.g., chemical coatings, anti-clogging finishes).

Common Operational Challenges & Maintenance

1. Blinding/Fouling: Clogging of mesh pores by fine colloids, fibers, or grease. Mitigation: Optimize belt washing system, use high-pressure shower nozzles, select anti-clogging weaves, or employ chemical conditioning agents.

2. Solid Carry-over ("Pinning"): Fine solids passing through the belt due to incorrect mesh size or belt damage. Mitigation: Re-evaluate mesh selection, inspect belt for wear/tears.

3. Excessive Wear or Damage: Caused by sharp debris, misaligned scrapers/blades, or chronic over-tensioning. Mitigation: Ensure effective preliminary screening (fine screens), regular equipment alignment checks, and proper tension control.

4. Routine Maintenance Essentials:

A. Daily: Inspect and clean belt washing showers.

B.Periodically: Check belt tension, alignment, and joint integrity; assess overall wear pattern.

C.Replacement: Replace belts upon significant physical damage, irreversible stretching, or a persistent decline in dewatering performance.

Polyester sludge dewatering belts are a mature, high-performance solution central to efficient sludge management. Their success lies in the synergistic combination of PET material properties and advanced weaving technology. A strategic selection process—considering sludge type, equipment parameters, and performance requirements—followed by disciplined operation and maintenance, is vital to maximizing dewatering efficiency, belt lifespan, and overall cost-effectiveness. Continuous innovation in weave designs and surface treatments further expands their capability to handle increasingly challenging sludge streams.

About [GOLDEN WAY]

[HEBEI GOLDEN WAY IMP&EXP CO., LTD] specializes in advanced industrial textiles for harsh processing environments. With decades of expertise in polymer engineering and filtration technology, we deliver solutions that enhance reliability, safety, and sustainability in chemical manufacturing worldwide.

Related News

Australia’s Beach Mat Exhibition

28 f, 2025

We are proud to announce our participation in a major beach mat exhibition held in Australia, marking a significant step in expanding our global presence.

28 f, 2025

We are the only professional beach mat manufacturer in China, dedicated to the design, production, and global distribution of high-quality beach mats

Letter of Intent – Already Signed in Malaysia

28 f, 2025

Letter of Intent for the Establishment of the Joint Institute for Future Technologies

Hot Products