11 October, 2025

Share:

A versatile innovation in industrial materials is transforming processes across key sectors. Polyester Spiral Mesh, known for its unique structural properties and exceptional durability, is proving to be a game-changing solution in the dryer sections of paper machines, the production of composite fabrics, and the critical drying/conveying stages of food and pharmaceutical manufacturing.

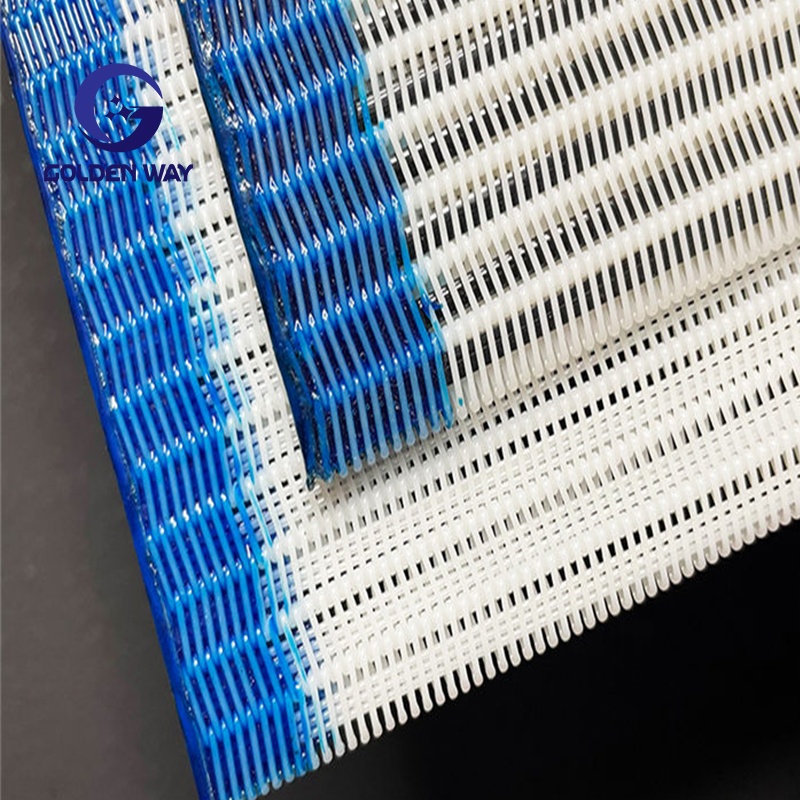

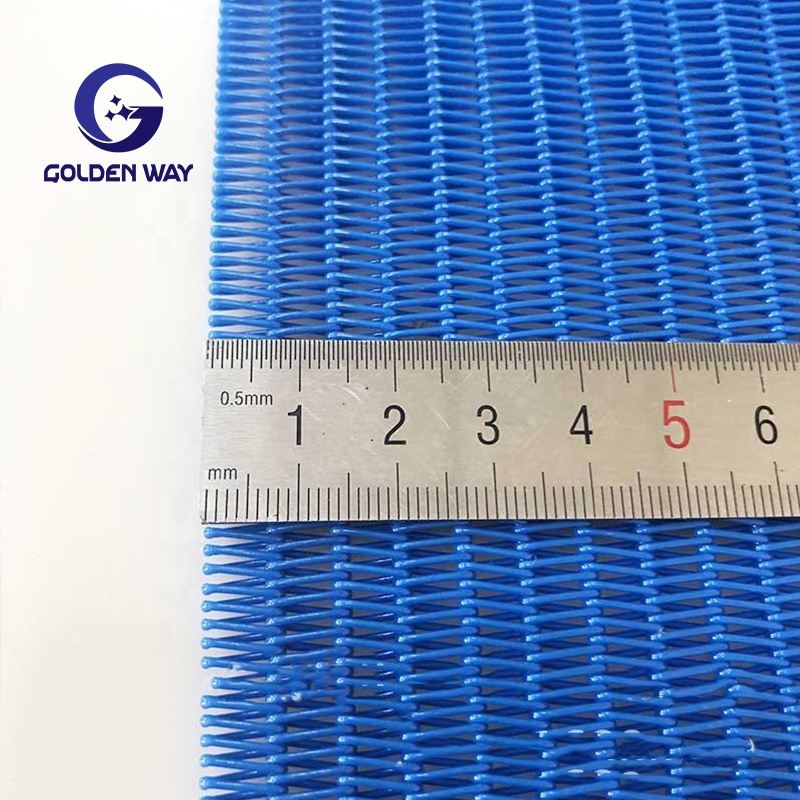

This advanced mesh, engineered from high-performance polyester monofilaments woven into a continuous spiral structure linked by transverse rods, offers a combination of benefits that traditional woven fabrics cannot match.

Unmatched Versatility and Performance

The fundamental design of Polyester Spiral Mesh delivers a suite of advantages critical to modern industrial efficiency:

Superior Airflow and Permeability: Its open, three-dimensional structure ensures maximum airflow, which is crucial for rapid and uniform drying. This significantly enhances thermal efficiency, reducing energy consumption in drying applications.

Exceptional Stability and Strength: The spiral construction provides outstanding dimensional stability, resisting elongation and shrinkage under high tension and temperature. This results in reliable, continuous operation with minimal risk of track deviation or edge damage.

Smooth, Non-Marking Surface: The knot-free, consistent contact surface is ideal for delicate materials. It prevents marking on premium paper grades, ensures the integrity of composite fabric layers, and provides a gentle, hygienic conveying surface for food and pharmaceutical products.

Easy Cleaning and Contamination Control: The smooth monofilament surfaces and open mesh design prevent material buildup and allow for easy, effective cleaning. This is paramount for maintaining hygiene standards in food and pharmaceutical processing and for reducing downtime in all applications.

Long Service Life and Reduced Downtime: Its robust resistance to abrasion, moisture, and microbial degradation ensures an extended operational lifespan, delivering a superior return on investment by minimizing replacement frequency and maintenance costs.

Industry-Specific Applications Driving Adoption

Paper Manufacturing: In the dryer section of paper machines, this mesh acts as a highly efficient dryer fabric. Its excellent breathability allows for rapid moisture vapor removal, leading to higher machine speeds, lower steam consumption, and improved paper quality.

Composite Fabrics Production: The mesh serves as an exceptional carrier and stabilizer during the production of non-wovens, technical textiles, and laminated fabrics. Its stability and heat resistance ensure precise handling of materials through coating, laminating, and curing processes.

Food and Pharmaceutical Processing: As a conveyor belt in dryers, coolers, and proofing systems, its hygienic properties take center stage. It is resistant to oils, fats, and cleaning chemicals, and its easy-clean design meets the stringent sanitary requirements of these regulated industries.

Polyester Spiral Mesh isn't just a component; it's a productivity tool. We see it enabling our clients in the paper, composite, and food sectors to achieve new levels of operational excellence, sustainability through energy savings, and product quality

The adoption of Polyester Spiral Mesh is a clear indicator of a broader industrial trend towards multifunctional, high-efficiency materials that reduce the total cost of ownership while enhancing process outcomes.

Related News

Australia’s Beach Mat Exhibition

28 f, 2025

We are proud to announce our participation in a major beach mat exhibition held in Australia, marking a significant step in expanding our global presence.

28 f, 2025

We are the only professional beach mat manufacturer in China, dedicated to the design, production, and global distribution of high-quality beach mats

Letter of Intent – Already Signed in Malaysia

28 f, 2025

Letter of Intent for the Establishment of the Joint Institute for Future Technologies

Hot Products