25 September, 2025

Share:

In the high-stakes environment of paperboard manufacturing, maximizing the efficiency of the press and dryer sections is paramount to profitability and product quality. A growing number of leading manufacturers are now achieving significant gains by upgrading to advanced Polyester Spiral Press Belts, a technology redefining performance standard for drying and conveying applications.

The dryer section of a paperboard machine presents a formidable challenge: to remove moisture efficiently while maintaining sheet integrity and high machine speeds. Traditional woven dryer fabrics can struggle with limitations in breathability, stability, and resistance to compaction, often creating bottlenecks.

Engineered for Peak Performance

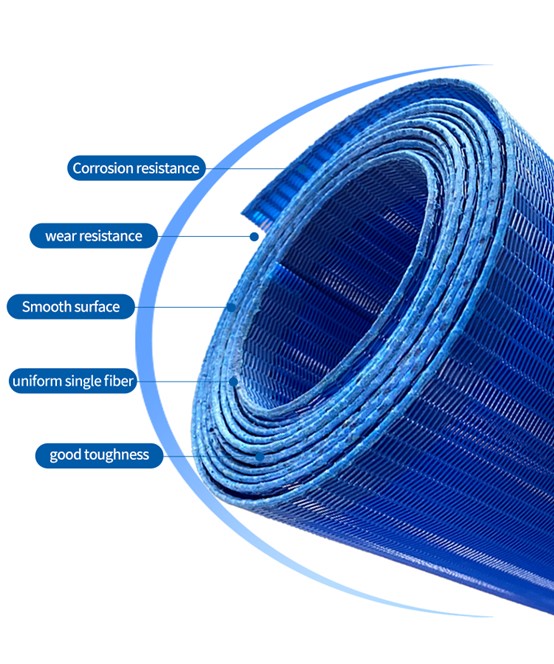

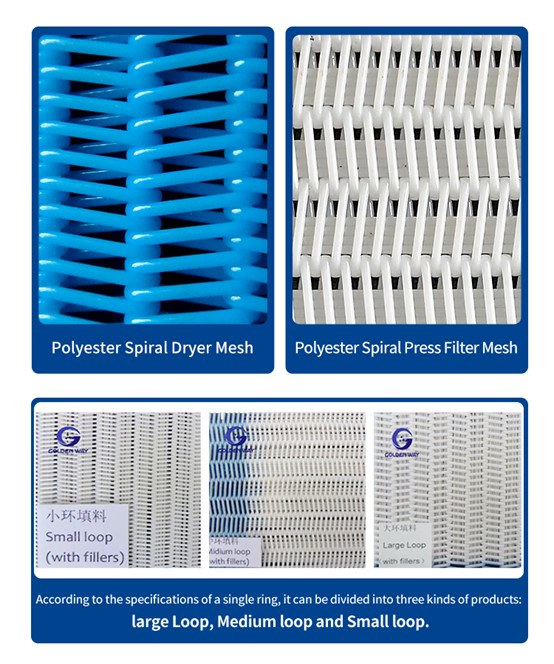

Polyester Spiral Press Belts, also known as spiral dryer fabrics, address these challenges through a unique engineered structure. They are constructed from spirally wound polyester monofilaments interlocked with transverse weft rods (CARL system). This design delivers several critical advantages:

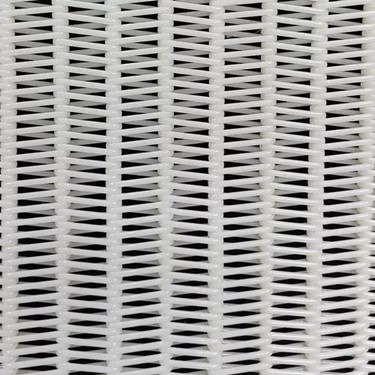

Unmatched Air Permeability and Drying Efficiency: The open, three-dimensional mesh structure provides an optimal path for steam to escape rapidly from the sheet. This eliminates the "air cushion" effect, improves heat transfer from the drying cylinders, and allows for higher machine speeds or reduced steam consumption.

Exceptional Stability and Smooth Surface: The spiral construction offers superior dimensional stability, resisting elongation and shrinkage. Its knot-free, smooth contact surface minimizes sheet marking, ensuring a high-quality finish on the paperboard and reducing the risk of sheet breaks.

High Resistance to Compaction and Long Life: The robust spiral links are designed to withstand the high pressures between cylinders and rolls without collapsing. This results in extended service life, reduced downtime for changes, and consistent performance over time.

Easy Cleaning and Reduced Energy Consumption: The smooth monofilament surface prevents the accumulation of pulp, fillers, and chemicals. This allows for easy cleaning with standard shower systems, maintains optimal permeability, and contributes to lower drive motor loads.

Proven Results in the Field

A major integrated paperboard mills recently retrofitted its dryer section with Polyester Spiral Press Belts, reporting dramatic improvements:

l 7% increase in machine speed due to more efficient dewatering and reduced break rates.

l 6% reduction in specific steam energy consumption, leading to substantial cost savings and a lower carbon footprint.

l Extended operational life, with the spiral belts outperforming the previous fabrics by over 40% in lifespan, drastically reducing maintenance costs and spare part inventory.

The Future of Drying Technology

As the paper industry continues to focus on sustainability and operational excellence, technologies that enhance energy efficiency are critical. Polyester Spiral Press Belts represent a significant step forward, not only by directly reducing energy use but also by enabling more stable, high-speed production with less waste.

"Spiral technology is no longer an alternative; it is becoming the standard for high-performance paperboard machines," said an industry expert. "The return on investment through energy savings and increased production capacity is clear and compelling."

Related News

Australia’s Beach Mat Exhibition

28 f, 2025

We are proud to announce our participation in a major beach mat exhibition held in Australia, marking a significant step in expanding our global presence.

28 f, 2025

We are the only professional beach mat manufacturer in China, dedicated to the design, production, and global distribution of high-quality beach mats

Letter of Intent – Already Signed in Malaysia

28 f, 2025

Letter of Intent for the Establishment of the Joint Institute for Future Technologies

Hot Products